- Home

- > News & Information > Exhaust Fume & Ducting Solutions

Exhaust Fume and Ducting Solutions

Summary

Vehicle exhaust in warehouses and manufacturing facilities can pose serious health risks if left unmanaged. Efficient fume and exhaust ducting captures carbon monoxide and harmful emissions at the source, keeping air clean, workers safe, and operations running smoothly.

This blog explores the technology, applications, maintenance tips, and benefits of modern modular exhaust ducting systems.

Table of Contents

What is Exhaust Ducting?

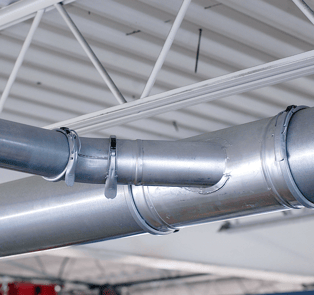

Exhaust ducting is a specialized system designed to capture carbon monoxide and other hazardous fumes emitted by internal combustion engines in indoor environments. Unlike general ventilation, these systems focus on removing contaminants directly at the tailpipe, preventing the spread of harmful gases throughout the facility.

Modern ducting solutions use modular, clamp-together systems to ensure airtight connections, reduce installation time, and minimize the risk of leaks.

Common Applications

Warehouses

Manufacturing Plants

Vehicle Maintenance Facilities

Cold Storage / Distribution Centers

Indoor vehicle traffic is frequent and requires consistent air quality control.

How Exhaust Ducting Works

Most vehicle exhaust ducting systems combine flexible hoses with rigid ductwork that connects directly to the vehicle tailpipe. Key features include:

Modular Design

Airtight Seals

Capture at the Source

Flexible Hose Options

By using modular components, these systems can be easily reconfigured if your facility layout changes or additional vehicle coverage is needed.

Materials and Design Options

Exhaust ducting comes in several construction materials depending on your facility’s needs:

Galvanized Steel duct: Durable, cost-effective, and suitable for most general warehouse environments.Stainless Steel duct: Resistant to corrosion, ideal for areas with moisture or high chemical exposure.

Aluminum duct: Lightweight and easy to install, suitable for mobile systems or temporary setups.

Custom fume hoods and extraction points can be designed to target specific work areas, maximizing airflow efficiency while reducing system size and cost.

Maintenance and Operational Efficiency

Maintaining a vehicle exhaust ducting system ensures long-term performance and reduces downtime:

- Inspect clamps and hose connections monthly for leaks or damage.

- Clean hoses and ductwork quarterly to prevent buildup of residue or debris.

- Check airflow rates regularly to ensure the system is capturing fumes effectively.

- Replace worn hoses promptly to avoid inefficiency or safety hazards.

Efficient ducting not only keeps air clean but also prevents mold, insect harbors, and other environmental concerns that can arise in warehouses and manufacturing areas.

FAQs: Exhaust Ducting Systems

Can I install a exhaust ducting system myself?

Modular systems like Nordfab® Quick-Fit® can be installed by skilled maintenance teams. Complex setups with multiple vehicles or long runs may require professional design.

How do I know the system is sized correctly for my facility?

The system should be designed to match the number of vehicles, tailpipe types, and facility layout. Airflow calculations and proper hose placement are critical for effective capture.

What maintenance is required?

- Monthly inspection of connections and clamps

- Quarterly hose and duct cleaning

- Replacement of worn components as needed

What materials are best for my application?

- Galvanized steel for general warehouses

- Stainless steel for moisture-prone or corrosive areas

- Aluminum for lightweight or mobile setups

For a tailored solution, DuctingSystems.com provides CAD layouts, parts lists, and budgetary quotes to simplify your next exhaust ductwork project. Call 888-659-2648 for expert guidance.

You may also like:

• Duct Parts & Supplies

• Dust Collector Duct Design

• 8 Reasons to Use Nordfab® Ducting